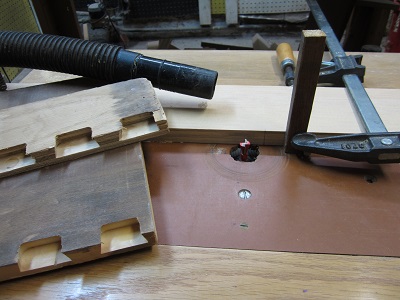

Just a quick update on my progress; I bought myself a new 1/2″ dovetail router bit ($20), and got to work cutting the joints. Almost half the time spent planning, setting up, and cutting tests. The first picture below shows the setup:

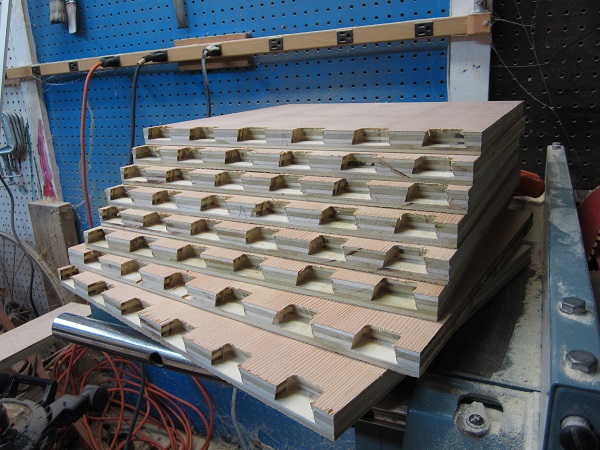

In the next picture you can see the results of a few hours at the router table cutting the half-blind dovetail coves in the backs. Notice how the coves don’t pass all the way through the boards: that’s the half-blind part. Initially I had hoped to place the cuts in identical locations on all the backs so that the tail half of the joints could be cut all in one pass, across all the seats at once. Alas, I don’t think that’s to be. There was just too much variability in my setup, even with the nifty jig.

Next I’ll need to clean up the backs of the coves to make them square with the surface, and chisel out the rounded corners. Then bevel the ends (8 degrees, remember?) cut the tails, and of course the joints will slide together neatly on the first try!